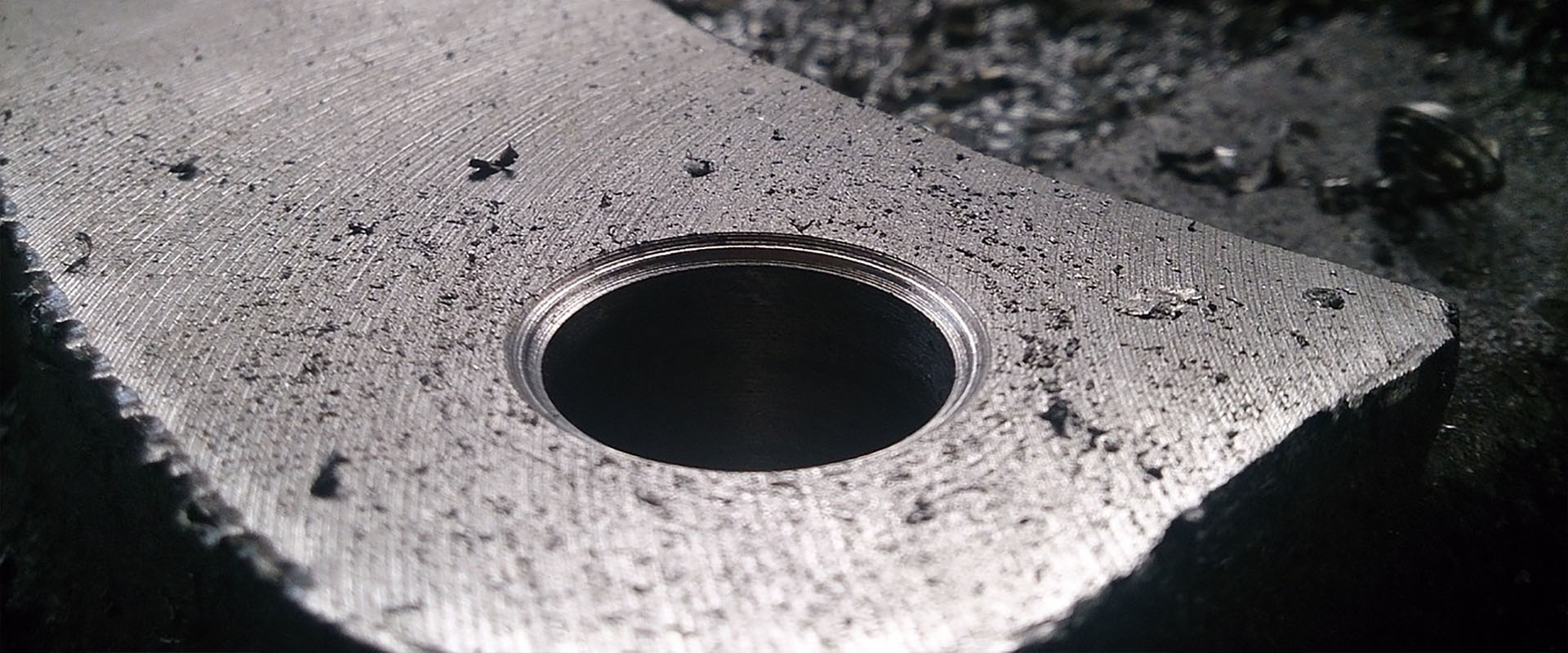

Construction and Molds

MOLD CONSTRUCTION WORKSHOP

The mold-making department, the central part of the connection between the design and production, consists mainly of numerical control machining centers and EDM machines, as well as the common machines of the tooling machines.

The specialization of personnel, constantly trained and updated, allows the production of latest-generation molds in a short time and with the precision that the market requires. It is said that the construction of molds for plastic materials is an art, because each work is different from the previous one and the ability of each operator to work in the best way possible makes the difference between a masterpiece and a failure.

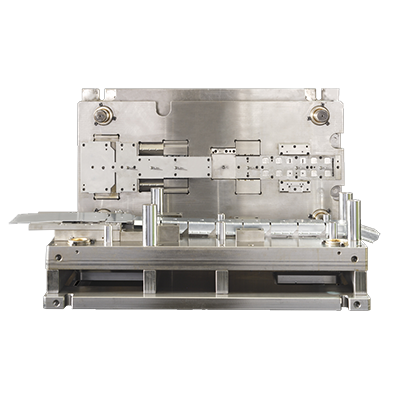

YOUR MOLD GUARANTEED TO LIFE

Delzano srl guarantees the molds to its customers for life without incurring additional costs. Thanks to the internal presence of the workshop building molds, all routine maintenance interventions caused by small breakages or deterioration are borne at our expense to guarantee a mold that is always functional.

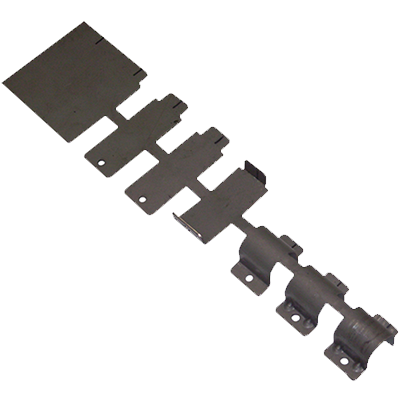

Shearing

The actual production of the product takes place in the cold sheet molding department. The machine park includes a series of tonnage presses between 40 and 200 t and is equipped with both traditional hydraulic machines and the recent electric machines, all in the network for a better control of the molding process; the internal mold construction workshop guarantees then the ordinary and extraordinary maintenance of the molds in reduced times.

The peculiarity of the company is the ability to print with extreme flexibility, as well as Iron coils also Stainless Steel, Brass, Copper, and Aluminum. All the materials we work on require appropriately constructed and conditioned molds and must be mounted on specially equipped presses for molding.

In addition to the molding of metal alloys, Delzano s.r.l. it works in the production of small series but also of large and continuous batches of finished products: according to the requests, the process is completed with the tumbling, galvanizing treatments, assembly and packaging, ensuring delivery times that meet the specifications customer’s need.

Sheet Metal Folding

Starting from the sheet of large sheet up to the piece of precision of complex shape, Delzano Srl, offers various possibilities for use in the bending of thin and medium thickness sheets.

Our machines work quickly and are used in a very productive and economically advantageous way in different sectors. The ability to realize bending processes internally allows us to offer our customers a finished product without having to resort to external processing.

Metal drawing

The drawing is part of the cold stamping of the sheets or the complex of operations that allow to obtain, without chip removal, through a plastic deformation objects of size and shape desired by sheets of metallic material (steel, copper, aluminum, light alloys) of limited thickness.

Drawing is the most difficult operation of cold forming by which a flat plate is transformed into a hollow body, through one or more passages. During this operation the material is subjected to considerable stress and compression stresses which modify the position of the fibers and for this reason requires the use of quality sheets.

The drawing operations are often accompanied by bending operations: operation with which objects of various shapes can be obtained without altering the thickness of the sheet.

Assembly of Components

Among the services offered to customers, Delzano S.r.l. it also carries out assembly activities of components for the most diversified uses: from the food sector, to the pharmaceutical sector, to the automotive sector, including, among other things, the textile, automation, electrical, nautical and furniture sectors. The assemblies are then checked by specific tests in order to deliver a product ready for the market and sale in freepass.

Punches and Matrices

- Amada

- Finn Power

- Rainer

- Trumpf

- Salvagnini

- Wiedemann

- EuroMAC

Quality Check

Quality check: to ensure the quality of processes, products, machinery and equipment.

To ensure quality, processes, products, machinery and equipment must meet a number of legal and contractual requirements. The complete quality control and certification services offered by us ensure compliance with all specified requirements.

Delzano Srl mechanics possess the safe skills and the indispensable resources to perform a quality control. In addition, providing inspection, verification, certification and analysis services, we are the first reference for customers who wish to ensure quality in all their products. We can therefore guarantee you trained and qualified technical personnel for the quick control of the quality of processes, products, machinery, equipment and systems of finished products.